Precision engineering and replication excellence.

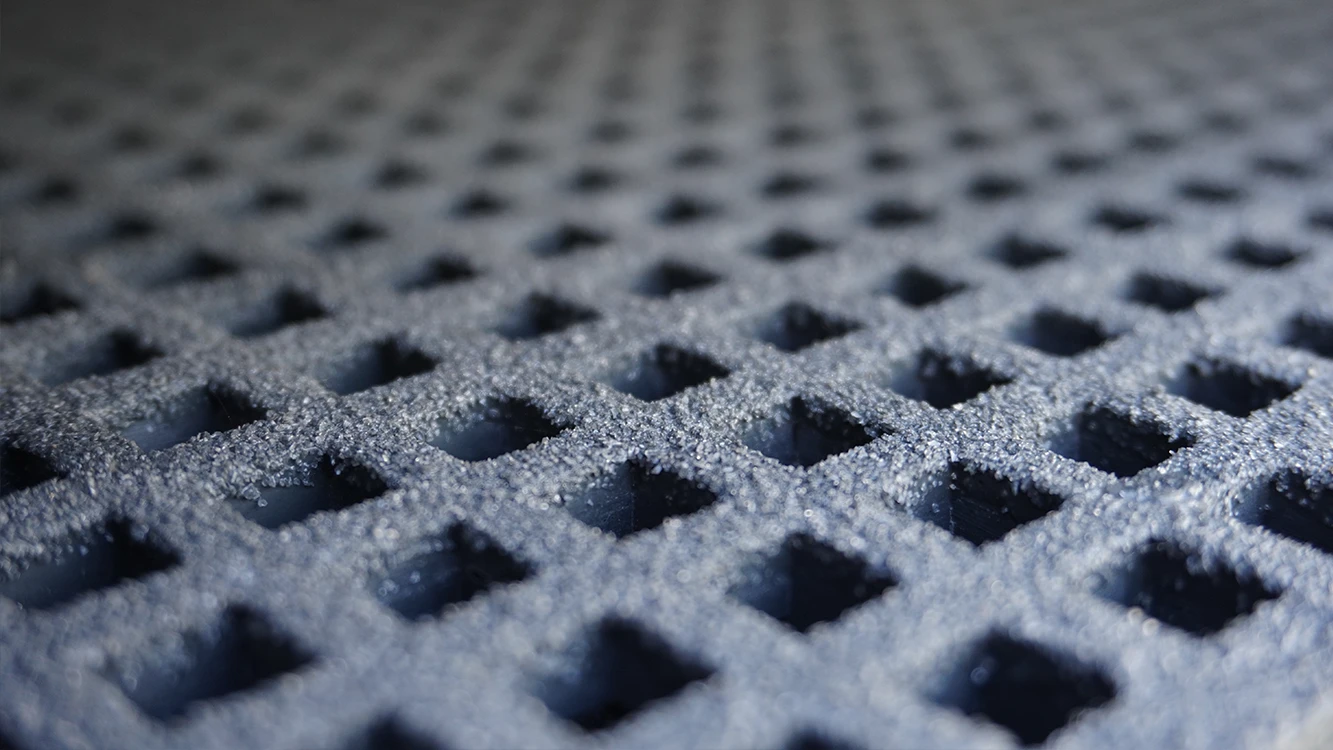

Computer numerical control (CNC) is a critical part of the manufacturing method for our walkways, fabrications, station canopies and structures. By using CNC machines, we are able to achieve a level of accuracy for the machining of standard Dura Profile sections for example that would be almost impossible to achieve through manual methods. Once parts have been machined, they are passed to our fabricators who assemble them with care, in accordance with the fabrication drawings produced by our Design Studio. The result is a precision finish that is consistent and repeatable time after time.

Our CNC technology is also used extensively within our station canopy projects, often to replicate existing fascia designs at heritage or listed stations. Our Design team will first scan the existing degraded canopy using our LIDAR scanning technology and then translate the data into a digital path which can be used to create intricate client-approved designs onto our patented composite daggerboard material. Following client approval of a sample piece, full production starts, with new low maintenance canopy sections delivered to site ready for install in as little as 2 weeks.